Electric Vehicle Course Categories

- Master Degree

- PG Course

- Startups/Business Course

- Job Course

- Research and Development

Masters Degrees (Electric Vehicles)

| Program Title | University | Duration |

|---|---|---|

| Master in Electric Vehicle Engineering | Sweden’s leading university | one-year programme |

| MSc Mobility Engineering | Politecnico | 2 years |

| MSc Automotive Engineering for Electric Vehicles | University of Bedfordshire | 1 yera |

| PG Program in Electric Vehicle Powertrain | Joint program with UPES and Academy of EV Technology | 10 Months |

| Certificate in EV Technology | Joint program with UPES and Academy of EV Technology | 3 Months |

Startups/Business Course

| Program Title | Offered by | Duration |

|---|---|---|

| EV EVSE Business Management Course for Entrepreneurs | Academy of EV Technology | one Month |

| Lithium-ion Battery Pack Assembly Line | Academy of EV Technology | One Month |

| Electric Vehicle Charging Station Design, Installation | Academy of EV Technology | 1 Month |

| Program Title | Offered by | Duration |

|---|---|---|

| PG Program in Electric Vehicle Powertrain | Joint program with UPES and Academy of EV Technology | 10 Months |

| Certificate in EV Technology | Joint program with UPES and Academy of EV Technology | 3 Months |

Certificate in EV Battery pack assembly line

The lithium-ion battery business in India is expected to be propelled by electric vehicles and energy storage systems (ESS) for commercial and residential uses. The recent discovery of Lithium reserves in J&K does come in as a new lease of life as it further enables India’s ambition to become self-sufficient in its energy storage needs. We face significant challenges in the EV ecosystem: insufficient raw material availability. The recent discovery of lithium resources will solve that challenge.

According to the GMI Research forecasts, the India Electric Vehicle Battery Market is estimated to touch USD 963 million by the end of 2026, growing at a CAGR of 25.3% during 2019-2026. The rising environmental concerns, followed by the increasing number of government initiatives to reduce carbon emission by incentivizing electric vehicles, are the significant factors contributing to the growth of the India Electric Vehicle Battery Market.

With a target of 50 GWh, the NITI Aayog plan would support the establishment of anywhere between three to ten giga-factories of 20 GWh to 5 GWh capacity each in the country. There is a dual recognition that the ecosystem needs to be developed, but that cannot be done overnight; it has to be achieved in a phased manner. Gujarat, which has already seen large-scale investments for Li-ion battery manufacturing, is offering additional support in the form of subsidized utilities under the state’s electronics policies. Telangana has announced the availability of 200 acres of land plus power and water for the manufacturing unit at a concessional rate. Andhra Pradesh, as early as 2017, announced the allocation of 200-400 acres for development of the electric mobility-focused industrial park.

Academy Of EV Technology will offer a course on Lithium Battery Pack Assembly course, covering li-ion cell to battery characteristic's, different parameters, EV battery Pack design aspect, calculation, assembly line unit detailing with financial aspects, govt guidelines, policies etc.

TRAINING METHODOLOGY:

Offline in house Classes:

AEVT offer in house class with hands-on practical, so that you can clear your doubts from AEVT experienced teacher and make battery module/pack at AEVT Lab.AEVT lab is a very unique lab - battery assemble line (proto type) with different cell parameter testing.

Through this technical knowledge and proto type battery pack making, you can grow your confidence.

Live Interactive Classes::

AEVT Live Interactive Class, where students and teachers meet together at schedule class time with whiteboard, voice and live video, Lectures and Question answer occur at the same hour.

Our expert faculty members take session on each paper that is delivered through live sessions. These sessions are joined by students from India and Abroad. Trainers will discuss in each class session about Key concepts, whiteboard calculation, design, costing, documentation, case studies and real life examples. Students also get chance to clarify their doubts / academic clarifications. If by any chance you miss these live classes, don't worry, each class recorded sessions are uploaded in the AEVT E-Library/LMS.

Hands-on Practical

We know that only theoretical knowledge by online or virtual classes are not sufficient to get full expertise. An individual needs a practical exposure to flourish in a Job or business market.

So we offer practical session at AEVT Lab/Workshop after completion of live interactive online classroom session .In this approach a trainees can fulfill his/her knowledge in a very effective way and time.

We offer project-based blended learning experiences that promote academic and career success for Technical Education.

Teaching and Learning Material

AEVT have dedicated online library (AEVT E-Library) facility for students and stored all Learning Material (E-book, class recording, business releated documents) at AEVT E-Library.

AEVT E Library System provides access to more than 100 + e-books covering all fields of knowledge, e.g. EV Battery - BMS, Charging Station Design, Installation, Government rules and Business opportunity etc and also we have a huge collection of national and international journals, case studies, research papers.Student can access this E-library for self study.

Eligibility

For Entrepreneurs, Startups:

Minimum Educational Qualifications: 12th Pass

Minimum age 18 years, No Upper Age bar

Medium:

English

Dedicated Service Desk for Startups - EDP Desk

"Ringfenced resource to support your business".

GATE Trust dedicated service desk will provide you with access to a group of engineers, advisors to supporting you and your business needs.

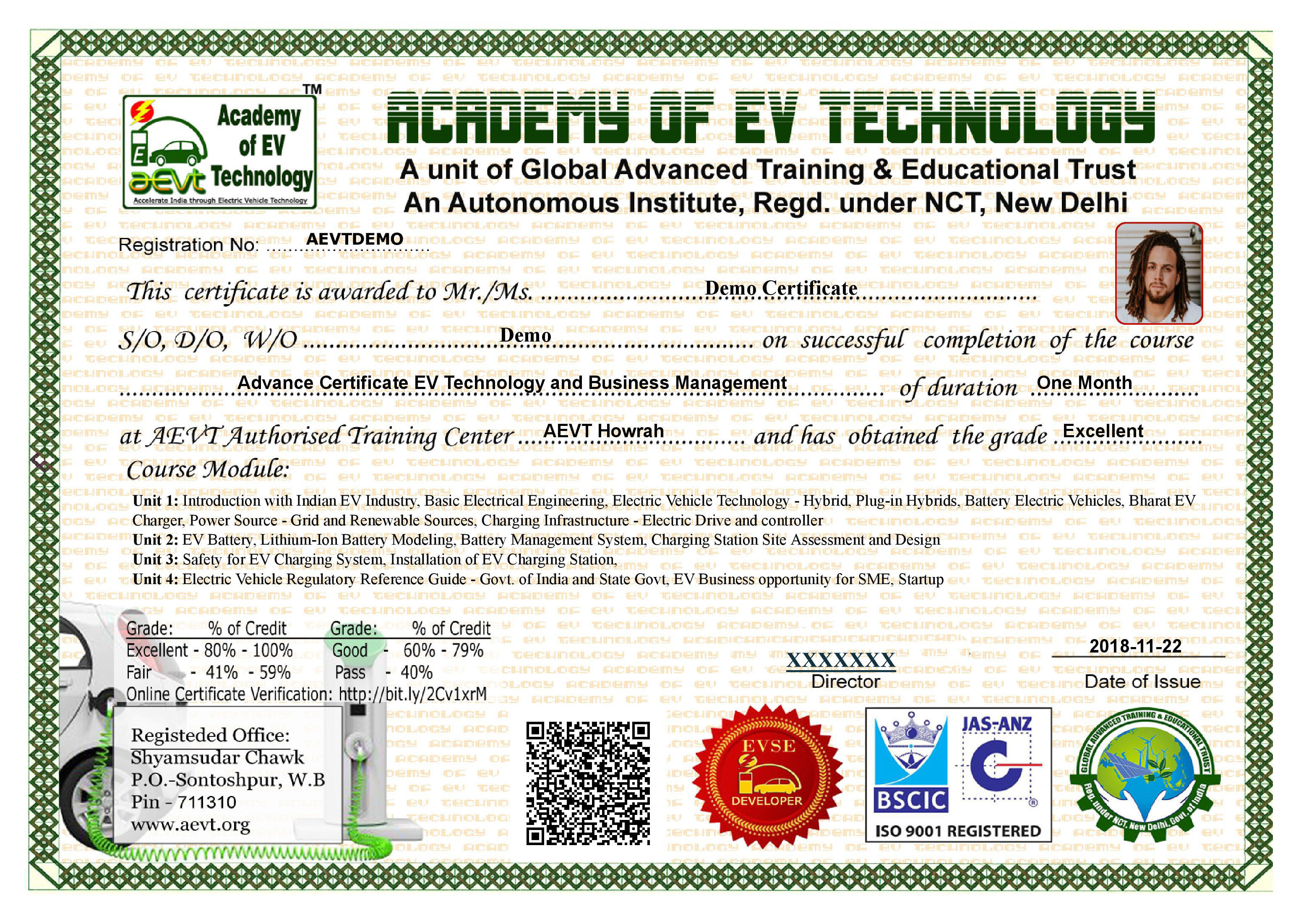

Certificate will be Awarded by

Academy of EV Technology, A Unit of Global Advanced Training & Educational Trust, Regd. under NCT New Delhi, Govt. of India

Start Lithium Ion Battery Pack Manufacturing Business

Local Lithium-ion battery production is expected to lower the cost of electric vehicles soon. This means entrepreneurs have great potential to start their lithium-ion battery businesses. The whole process may seem simple, but knowledge and skill required, like

1. be sure you understand how batteries are made

2. selected which market segment best to enter

3. licenses, permissions, or approvals required for operating a battery factory and many more …

Through all of the potential knowledge and skills, you can be better prepared for whatever comes your way.

Know the eco-friendly recycling competence and know-how that can provide a substantial quantity of these metals to Indian industry as well as internationally for manufacturing of Lithium-Ion Battery.

Course Syllabus:

This course will deliver from Solar Energy storage Lithium-ion battery to Electric Vehicle Li-ion Battery, Battery pack assembly process and equipment, raw materials, Machinery availability & vendor selection, Understanding Finance Basics & Business Model.BFC

A brief classification of li Ion cell technology and its electro-chemistry. Advantage and disadvantages of over different cell technologies.

- BATTERY ENERGY STORAGE SYSTEM (BESS)

- Relationship between Power and Energy

- Energy storage capacity

- Type of Battery / Cell

- Lithium-ion cells Cathode and Anode Materials

- Type of Lithium-ion Cell

- Main characteristics of lithium cell chemistry types

- Comparison of Lithium-ion Chemistries

- Safer battery materials

- Indian Li-ion Battery manufacturers

BCP

Know your Lithium-ion Cells, Cell Specifications & Performance Parameters. Classification of li-Ion cell technology and its electro-chemistry. Advantages and disadvantages of over different cell technologies

- Capacity, Capacity Retention

- Rated Voltage and Operating Voltage

- cell Datasheet

- Working voltage, Self –discharge voltage

- Continuous current and Peak Current

- Constant voltage / constant current(CVCC)

- C-rate, c-rate effects

- State of Charge (SOC)

- Li-ion Battery Voltage vs SoC

- State of Health (SOH)

- State of power (SOP)

- Internal resistance

- Depth of Discharge (DoD)

- Cycle life of Li-ion batteries

- Lithium Batteries Degradation

- Lithium Ion Battery Failure Modes

- Battery Thermal Runway

- Degrade of Battery Pack cycle

LiCC

An industry detail of Li-ion battery cells, covering the most popular sizes, formats, and chemistries. Given the diversity of Li-ion cells available, the focus is on cylindrical and prismatic cells in metal cases. A brief discussion on li-ion cell chemistry, Cell Anode, Cathode, Electrolytes, binder and Separators materials

- Cell Chemistry Trends

- Cell Anode and Cathode materials

- Cathode Metal Composition

- Active Material, Inactive Material, SEI formation

- Dendrite growth

LiCA

A brief discussion on insights into architecture, design and manufacture of electrodes for lithium-ion cell, Cell Anode, Cathode, Electrolytes, binder and Separators materials.

- This chapter investigates the effects of electrode thickness, porosity, pore size and particle size at the electrode level.

- Architecture design and manufacturing processes for high-performing lithium-ion batteries

- Lithium ion battery Basic Structure

- Cell components

- Anode, Cathode, Electrolytes and Separators materials

- CID, PTC, Safety Vent, Gasket, Plastic Parts

- RAW MATERIALS TO SUBCOMPONENTS

- Common sizes of cylindrical Li-ions

BTM

This chapter identified analyses and approaches that engineers should consider when they design a battery thermal management system. A brief discussion on Thermal Design of Battery Pack.

- Thermal runaway of Battery Pack

- Anode active material failure mechanism

- Cathode active material failure mechanism

- Electrolyte failure mechanism

- Separatore failure mechanism

- Current collector failure mechanism

- Required Functions of Thermal Design

- Low temperature effects

- High temperature effects

- Modes and Function of Battery Thermal Management Systems

- Air Cooling System

- Liquid Cooling System

- PCM material cooling system

BMS

Learn the high-level basics of what role battery management systems (BMSs) play in power design and what components are necessary for their basic functions.

- What the BMS does for battery?

- Function of BMS - Safety, Performance, Longevity, Consistence, Temperature Monitoring and control

- Type of BMS

- Cell Balancing

- Real Time Operating System of BMS

- Example of BMS Wiring Diagram

- How we can select perfect BMS for your battery pack?

BPC

Battery pack differ in size, geometry, and individual cell parameters as capacity and supplied power. A brief discussion on li-ion cell selection, BMS selection for different types of battery.

- Design Considerations of Battery Pack

- Cell Selection

- BMS Selection, Thermal Selection

- High Voltage Side Design

- Low Voltage Side Design

BPS

A battery pack consists of cells connected and made into modules, and modules connected into series and parallel connections to suffice the overall load requirements. A brief discussion of different sizes of battery pack used for electric vehicle & energy storage.

- How to make a Battery Pack?

- The basic calculations that are used in battery design

- Battery pack Technical Specification

- Battery pack designing

- Battery Module and Battery Pack Construction Methods

- Cylindrical and Prismatic Battery Pack

BPA

A brief discussion of battery module/pack making equipment/accessories. Trainees can learn how to make battery modules and Pack.

Battery Pack Accessories

- Material need to assemble battery Modules & pack

- Wires, connector selection, heat shrink, cell holder

- Different types of accessories related to battery pack construction

Battery Module & Pack Making

Battery module / Cell block assembly process- Supply and testing of battery cells & sorting

- Cleaning of cells (plasma cleaning)

- Stacking of modules to form cell block

- Module Formation, Spot Welding, Laser welding

- Thermal management - Application of glue,

- Insertion of cells in modules- Pre-assembly

- Busbar installation

- Module BMS integration, Testing

- Screw fitting of battery module housing

- Integration of cell block in pack

- Application of temperature conductive paste

- Screw fitting of battery housing (housing substructure + housing upper structure)

- Flashing of modules

- Leak testing (helium)

- EOL testing (source-drain)

- Insulation test

- Failure test

CPT

Battery cell testing helps develop better electric vehicle batteries that pack more power density to give longer range performance. Batteries go through an acceptance inspection before they are put together into modules and packs.

- Cell, Module and Pack industry slandered Test

- Testing Equipments and Lab

BPAL

A brief knowledge of Battery Pack Assembly Line development, required machinery details (manual, semi-auto and automatic production line), national & international vendors contact details, required lenience and documents, Financial Report.

Battery Pack Assembly Line

- Manufacturing process of battery pack

- Safety Considerations for BMS (Thermal Runaway, Short Circuit Detection etc)

- Functional Safety Overview

- Brief discussion about different machineries used in manufacturing

- Flow chart of assembly process of li ion battery pack

- Technical details of manufacturing machineries

Battery Pack Assembly Line Development

- Li-ion Battery Assembly Line

- Assembly Machinery and Functional Specifications

- Different size of Module and Pack

- List of Vendors of Raw materials and Machinery supplier

Financial Projection of Li-ion battery pack Manufacturing

- Cost analysis of different machineries and manpower requirements

- Return of Investment (ROI) of li ion battery pack business

- Business projection to start a li ion battery pack business

LBO

A business guide and motivation session for startups, entrepreneurs on Lithium-ion Battery Pack Assembly business and Battery Swaping business.

Future trends in Energy Storage Battery and Customized Battery

- Energy Storage Battery Solar Street Light Battery, Outdoor Battery

- Industrial Energy Storage Battery

- Customized Battery -

Customized solution on demand for Consumer electronics, Smart Home Appliance - Floor Cleaner, Vacuum Cleaner, Smart Door Lock, Smart Camera, Home Light, Smart Lamp, drown battery etc

Trends in Indian electric vehicle domain

- 2 wheeler and 3 wheeler battery market

- Wireless charging of EV

- Battery swap technology

Business Model/Case Study

- What is the size of the EV market in India?

- Govt. Policies and Regulations

- Business models,

- Choose best product/item as per your planing

- Battery swapping,

Lab Practical

- Cell Selection - Ah testing, IR testing

- Charging Discharging test, cell balancing

- Battery Pack Construction

- Module/Pack Spot Welding

- BMS Selection and Connection (as per System Design)

- Pack testing

- Battery Pack Casing

- Battery Pack Leveling

- Battery Pack Boxing

Course Fee

Today's Discount Offer 18%

Indian candidates Fees

Registration Fee pay to Head Office

Training Fee pay to our Branch after registration

For online class, Fees Pay to Head Office

Foreign Candidates Fees

Course Fee: $ 450 USDAfter Discount, Course Fee: $ 369 USD

All Fees Excluding 18% GST

Submit Registeration for this course:

Submit Registration

Admission Process

- Submit Registration

- Admission cell will check form data and they will inform you to pay Course fees

- Deposit Course fees

- Admission cell will send your E-registration certificate and E-library access

- Training cell will send you class schedule

- Study options:

- 2 Month (1 month in-house Technical and commercial class and onside practical, 1 month project work)

- For working Professionals: 2 Months (1 month weekend in-house Technical and commercial class and onside practical, 1 month project work)

- For online Live class: 2 Months (1 month online Technical and commercial class at night 8PM to 10PM (IST) and 1 month project work)

- Training cell inform you about practical session at the end of theory class session

- Exam cell will conduct online examination and send E-Certificate, E-marksheet

- EDP Desk will provide business guide/support for you

Become an EV Expert with Verified Skill Certification

1. An Autonomous Institute registered under NCT, Govt. of India under Indian Trust Act.

2. Registered Under NGO-DARPAN, NITI Aayog Govt. of India

3. ISO 9001:2015 registered Educational Trust

4. Registered under 80G and 12A and CSR Act, Govt. of India

5. Practical and Research Lab at GATE Trust Howrah, West Bengal

6. GATE Research - Research unit of Global Advanced Training and Educational Trust. You can Write & Publish a Review/Research paper,

Quick Inquiry Form

Interactive Session

Practical & Doubt Session

E-Library Study Materials

Online Evaluation