MSME Govt of India Registered Autonomous institution.

Special session for working professionals, Business owners

EV Technology & Business Management - Techno Commercial course for Business (Online)

Course Syllabus

1. EV Market Scenario and Business Opportunities

The global lithium-ion battery market, driven by the growth of electric vehicles (EVs) and renewable energy integration, is experiencing rapid expansion.

Topics covered:

Lithium Ion Battery Technology Overview, Battery Technology Fundamentals, Market Scenario and Business Opportunities, Lithium-ion Battery Raw Materials and India's Position, Government Policies and Incentives, Electric Vehicle Market Trends in India

Topics covered:

Lithium Ion Battery Technology Overview, Battery Technology Fundamentals, Market Scenario and Business Opportunities, Lithium-ion Battery Raw Materials and India's Position, Government Policies and Incentives, Electric Vehicle Market Trends in India

Key Learning Outcomes:

Develop the ability to analyze market trends, identify growth segments, and understand the competitive landscape within the EV industry. Understand the role of government incentives and regulations in shaping the market and learn strategies for attracting investment in the EV sector.2. Overview of Electric Vehicle Technology

Understand the design and function of key electrical systems, including batteries, motors, motor controllers, energy storage devices, including advanced batteries,

and charging station topologies.

Topics covered:

Electric vehicle configuration Vehicle Dynamics - Types of Electric Vehicle - Hybrid Electric Vehicles, Plug-in Hybrids, Battery Electric Vehicles, Type of Charger,

Topics covered:

Electric vehicle configuration Vehicle Dynamics - Types of Electric Vehicle - Hybrid Electric Vehicles, Plug-in Hybrids, Battery Electric Vehicles, Type of Charger,

Key Learning Outcomes:

Learn about the design and implementation of power electronics for electric drivetrains and charging infrastructure.3. Different type of Lithium-ion battery

Lithium-ion batteries are widely used due to their high energy density, light weight, and long lifespan, making them suitable for various applications, including portable electronics, electric vehicles, and energy storage systems.

Topics covered:

Battery Introduction, Battery Types, Relationship Between Power, Energy, and Applications, Comparison of Different Battery Chemistries, Advantages and Disadvantages of Lithium-ion vs. Sodium-ion Batteries, Composition and Reactivity of Lithium-ion Batteries, Key Properties of Lithium-ion Battery Chemistries, Lead-Acid Batteries, Nickel Batteries, Lithium-Ion Batteries, Lithium Battery Applications and Chemistries, Types of Lithium-Ion Batteries, Battery Cell Selection Parameters, Lithium Cobalt Oxide (LCO) Cell Characteristics, Lithium Manganese Oxide (LMO) Cell Characteristics, Lithium Nickel Manganese Cobalt Oxide (NMC) Cell Characteristics, NMC Cell for Electric Vehicles, Lithium Iron Phosphate (LFP) Battery Characteristics, LFP Battery Advantages and Disadvantages, LMFP Battery and Performance Comparison, Prismatic and Blade Cells and Battery Manufacturing and Import,

Lithium Titanate (LTO) Battery, Comparison of Battery Chemistries, C-rate Explained, Battery Overcharging and Safety, Short Circuit and Mechanical Damage Tests and Field Testing of Cell Stability

Topics covered:

Battery Introduction, Battery Types, Relationship Between Power, Energy, and Applications, Comparison of Different Battery Chemistries, Advantages and Disadvantages of Lithium-ion vs. Sodium-ion Batteries, Composition and Reactivity of Lithium-ion Batteries, Key Properties of Lithium-ion Battery Chemistries, Lead-Acid Batteries, Nickel Batteries, Lithium-Ion Batteries, Lithium Battery Applications and Chemistries, Types of Lithium-Ion Batteries, Battery Cell Selection Parameters, Lithium Cobalt Oxide (LCO) Cell Characteristics, Lithium Manganese Oxide (LMO) Cell Characteristics, Lithium Nickel Manganese Cobalt Oxide (NMC) Cell Characteristics, NMC Cell for Electric Vehicles, Lithium Iron Phosphate (LFP) Battery Characteristics, LFP Battery Advantages and Disadvantages, LMFP Battery and Performance Comparison, Prismatic and Blade Cells and Battery Manufacturing and Import,

Lithium Titanate (LTO) Battery, Comparison of Battery Chemistries, C-rate Explained, Battery Overcharging and Safety, Short Circuit and Mechanical Damage Tests and Field Testing of Cell Stability

Key Learning Outcomes:

Equip students with a comprehensive understanding of Li-ion batteries - Learning about the different positive electrode materials, their synthesis, and their impact on battery performance and lifespan. Gaining knowledge on battery safety, handling best practices, and the mechanisms that lead to thermal runaway.4. Lithium-ion Cell Parameters

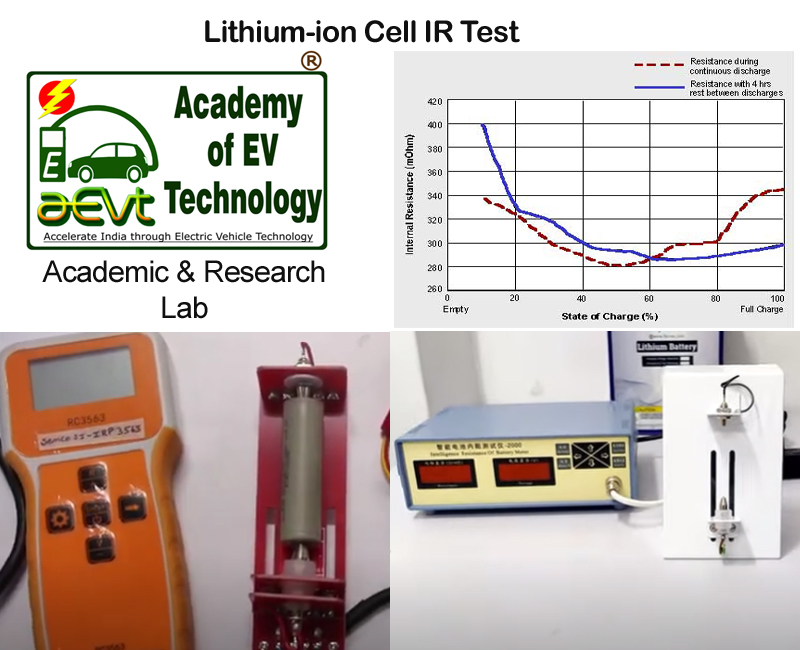

Lithium-ion cell parameters define its electrical and physical characteristics. Key parameters include voltage (nominal, charge, discharge cut-off), capacity (rated and nominal), internal impedance, C-rate (discharge and charge rates), and operating temperature range. These parameters influence cell performance, lifespan, and safety.

Topics covered:

Introduction to Cell Parameters, Key Battery Parameters, Charge and Charge Capacity, Columbic Efficiency and Capacity Retention, Battery Capacity and Voltage, Nominal Voltage and State of Charge, Nominal Cell Capacity and Discharge, Temperature Effects, Actual Cell Capacity and Capacity Fade, Battery Repair and Cell Health, Open Circuit Voltage and State of Charge (SoC), Self Discharge, Continuous and Peak Current, Constant Current Constant Voltage (CCCV) Charging, Fast Charging vs. Slow Charging, C-Rate Definition and C-Rate Calculation, Impact of C-Rate on Battery Performance and Heat Generation, State of Charge (SOC) and State of Health (SOH), Open Circuit Voltage (OCV) and SOC Estimation, Internal Resistance and Temperature Effects, Cycle Life, State of Power (SOP), Battery Testing and Capacity Measurement, Causes of Battery Degradatio, Battery Restoration and Degradation, Maximum Power Point and cell Efficiency, Battery Management System (BMS), Temperature Effects on Battery Performance, Thermal Runaway and Safety, Strategies for Small Battery Manufacturers, Session Summary and Homework Assignment.

Topics covered:

Introduction to Cell Parameters, Key Battery Parameters, Charge and Charge Capacity, Columbic Efficiency and Capacity Retention, Battery Capacity and Voltage, Nominal Voltage and State of Charge, Nominal Cell Capacity and Discharge, Temperature Effects, Actual Cell Capacity and Capacity Fade, Battery Repair and Cell Health, Open Circuit Voltage and State of Charge (SoC), Self Discharge, Continuous and Peak Current, Constant Current Constant Voltage (CCCV) Charging, Fast Charging vs. Slow Charging, C-Rate Definition and C-Rate Calculation, Impact of C-Rate on Battery Performance and Heat Generation, State of Charge (SOC) and State of Health (SOH), Open Circuit Voltage (OCV) and SOC Estimation, Internal Resistance and Temperature Effects, Cycle Life, State of Power (SOP), Battery Testing and Capacity Measurement, Causes of Battery Degradatio, Battery Restoration and Degradation, Maximum Power Point and cell Efficiency, Battery Management System (BMS), Temperature Effects on Battery Performance, Thermal Runaway and Safety, Strategies for Small Battery Manufacturers, Session Summary and Homework Assignment.

Key Learning Outcomes:

Understand Core Parameters, Learn Parameter Estimation & Measurement, Apply knowledge to evaluate and select appropriate cells for applications such as electric vehicles and portable electronic devices.5. Lithium-ion Cell Chemistry

Lithium-ion batteries utilize the movement of lithium ions between a cathode and an anode to generate electrical current during discharge and reverse the process during charging. These ions move through an electrolyte, while electrons flow through an external circuit, creating the electric power.

Topics covered:

Lithium Ion Battery Components, Common Lithium Ion Cell Chemistry, Cathode Material and Function, Anode Material and Function, Electrolyte and Separator Roles, Solid Electrolyte Interface (SEI) Layer and Lithium Plating/Dendrite Formation, Electrochemical Reactions During Charge and Discharge, Lithium Cobalt Oxide (LCO) Cell, Lithium Nickel Cobalt Aluminum Oxide (NCA) Cell, Lithium Manganese Oxide (LMO) Cell, Lithium Iron Phosphate (LFP) Cell, Lithium Nickel Manganese Cobalt Oxide (NMC) Cell, Lithium Titanate Oxide (LTO) Cell, Anode Materials Beyond Graphite, Current Collectors, Separator Properties, Dendrite Formation and Battery Failure, Battery Life Cycle and Replacement, Recycling of Lithium-ion Batteries, Advancements in Lithium-ion Battery Technology, Quality and Manufacturing in Battery Production, Session Summary and Hometask Assignment.

Topics covered:

Lithium Ion Battery Components, Common Lithium Ion Cell Chemistry, Cathode Material and Function, Anode Material and Function, Electrolyte and Separator Roles, Solid Electrolyte Interface (SEI) Layer and Lithium Plating/Dendrite Formation, Electrochemical Reactions During Charge and Discharge, Lithium Cobalt Oxide (LCO) Cell, Lithium Nickel Cobalt Aluminum Oxide (NCA) Cell, Lithium Manganese Oxide (LMO) Cell, Lithium Iron Phosphate (LFP) Cell, Lithium Nickel Manganese Cobalt Oxide (NMC) Cell, Lithium Titanate Oxide (LTO) Cell, Anode Materials Beyond Graphite, Current Collectors, Separator Properties, Dendrite Formation and Battery Failure, Battery Life Cycle and Replacement, Recycling of Lithium-ion Batteries, Advancements in Lithium-ion Battery Technology, Quality and Manufacturing in Battery Production, Session Summary and Hometask Assignment.

Key Learning Outcomes:

Understand the physical concepts of thermodynamics and kinetics involved in electrochemical reactions, including redox principles. Learn to select appropriate battery cells and chemistries (e.g., NMC, LFP) based on specific application requirements, such as for electric vehicles.6. Lithium-ion Cell Architecture

Lithium-ion Cell Architecture includes an anode, cathode, separator, electrolyte, and current collectors. The anode and cathode store lithium ions, the electrolyte facilitates ion transfer, the separator prevents short circuits, and the current collectors enable electron flow.

Topics covered:

Types of Cells, Cell Construction and Differences (cylindrical, pouch, prismatic, coin, or button), Internal Components and Assembly, Cylindrical Cell Casing, Anode (Negative Plate), Separator, Separator as a Safety Device, Cathode (Positive Plate), Electrolyte Injection, Electrolyte and Lithium Salts, Protection Vent and Safety Features, Current Interrupt Device (CID), Positive Temperature Coefficient (PTC) Device, Cell Casing and Additional Safety, Scalability and Cost of Battery Manufacturing, India's Manufacturing Growth, Global Business Dynamics and Dependency, Hometask Assignment.

Topics covered:

Types of Cells, Cell Construction and Differences (cylindrical, pouch, prismatic, coin, or button), Internal Components and Assembly, Cylindrical Cell Casing, Anode (Negative Plate), Separator, Separator as a Safety Device, Cathode (Positive Plate), Electrolyte Injection, Electrolyte and Lithium Salts, Protection Vent and Safety Features, Current Interrupt Device (CID), Positive Temperature Coefficient (PTC) Device, Cell Casing and Additional Safety, Scalability and Cost of Battery Manufacturing, India's Manufacturing Growth, Global Business Dynamics and Dependency, Hometask Assignment.

Key Learning Outcomes:

Apply knowledge to design and develop efficient, safe, and sustainable battery solutions for industries like electric mobility and energy storage.7. Battery Management System (BMS)

Topics covered:

Battery Management System (BMS), BMS Role in Electric Vehicles (EVs), Core Functions of BMS, Types of BMS, Key Functions of BMS: Protection, Cell Balancing, Monitoring, Communication, Customization of BMS, BMS Customization and Market Competition, Comparison of European and Chinese Technology, BMS Core Functions, Cell Imbalance Issues, Thermal Runaway Scenario, Necessity of Cell Balancing, Constant Voltage Charging and Balancing, Active Cell Balancing, DC-DC Converter Functionality, Comparison of Balancing Methods, Battery Pack and BMS Integration, BMS Operating System, Advanced BMS Functions, Battery System Control Unit, Real-Time Operation and Safety Unit, Secondary BMS Functions and Interlock System, Benefits of an Advanced BMS, Centralized vs. Distributed BMS, Protection Circuit Board (PCB) vs. BMS, BMS in Series and Parallel Connections, Battery Pack Design Considerations, Battery Thermal Management and BMS Integration, Cost and Market Considerations, Challenges in Indian Development, Home Task BMS Datasheet analysis

Key Learning Outcomes:

Understand the basic components, architecture, and functional blocks of a BMS. Learn how to monitor, estimate, and protect batteries, including cell balancing, State-of-Charge (SOC) and State-of-Health (SOH) estimation, and thermal management. Apply BMS knowledge to design, implement, and troubleshoot systems for electric, hybrid vehicles and renewable energy storage battery design.8. Battery Thermal Management System (BTMS)

An electric vehicle's battery thermal management system (BTMS) is crucial for maintaining optimal battery performance, safety, and lifespan. It regulates the temperature of the battery pack, preventing overheating or overcooling by utilizing cooling and heating systems.

Topics covered:

Thermal Management Overview, Lithium-ion battery optimum temperature, Importance of Temperature Control, Thermal Runaway, Sources of Temperature Instability, Non-uniform Aging, Heat Generation and Dissipation, Types of Thermal Management Systems, Air Cooling System, Liquid and Refrigerant Cooling, Refrigerant cooling, Phase Change Materials and Comparison, Home Task.

Topics covered:

Thermal Management Overview, Lithium-ion battery optimum temperature, Importance of Temperature Control, Thermal Runaway, Sources of Temperature Instability, Non-uniform Aging, Heat Generation and Dissipation, Types of Thermal Management Systems, Air Cooling System, Liquid and Refrigerant Cooling, Refrigerant cooling, Phase Change Materials and Comparison, Home Task.

Key Learning Outcomes:

Identifying and selecting appropriate components for a BTMS, including fans, pumps, heat exchangers, and controllers. Learners will understand the purpose and operation of components in air and liquid cooling systems for battery packs.9. Lithium-Ion Cells Battery Test

Tariff Based Competitive Bidding Process for Procurement of Power from Grid Connected Solar PV Power Projects.

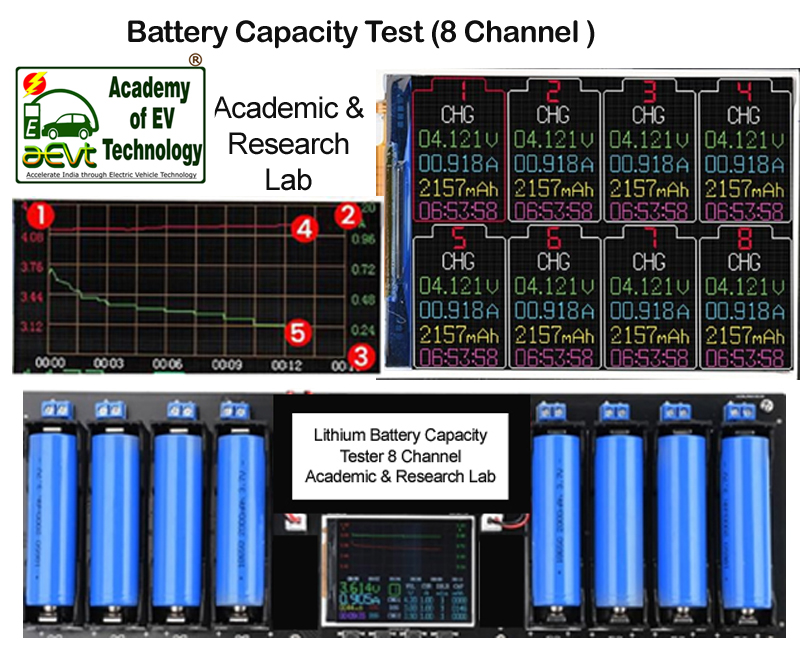

Topics covered:

Battery Validation Lab, Battery Cell Testing - Lithium-ion Cell actual capacity test, OCV and IR test, BMS Test, Thermal Cycling Test, Over-charging test, Bureau of Indian Standards (BIS) tests, How to get a BIS certificate,

Battery Repairing - Steps to test Battery health, IATA Lithium Battery Safety Regulations (LBSR) 2025, Lithium Battery Testing Standards

Topics covered:

Battery Validation Lab, Battery Cell Testing - Lithium-ion Cell actual capacity test, OCV and IR test, BMS Test, Thermal Cycling Test, Over-charging test, Bureau of Indian Standards (BIS) tests, How to get a BIS certificate,

Battery Repairing - Steps to test Battery health, IATA Lithium Battery Safety Regulations (LBSR) 2025, Lithium Battery Testing Standards

Key Learning Outcomes:

Learn various performance tests for battery cells and modules, such as those measuring capacity, voltage, and internal resistance. Enable learners to apply their knowledge to improve system performance, drive better design decisions, and ensure compliance in the energy storage market.10. Battery Module / Pack Design

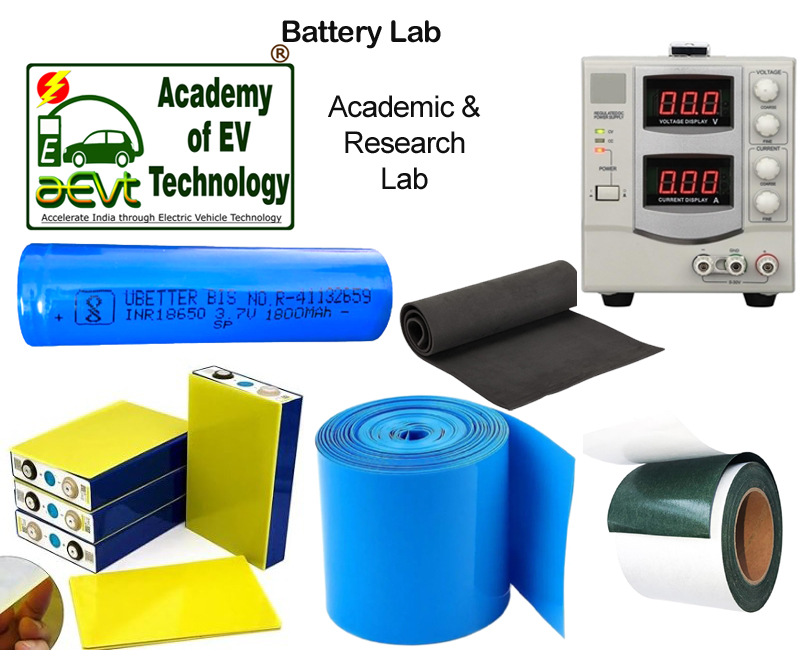

A lithium-ion battery module or pack design involves strategically arranging individual cells into modules, and then connecting those modules to achieve the desired voltage and capacity for a specific application. This design process considers factors like cell type, cooling, safety, and overall system integration.

Topics covered:

Pack Design Steps, Identify Application, Choose cell chemistry, Series –parallel configuration, Choose required BMS, Choose TMS, Choose Pack cabinet and other parts and equipments, Pack Technical Specification.

Battery Pack Cells configuration, Basic calculations that are used in battery design, Case study of different OEM battery, Module BMS connection, Custom Battery Packs - Customization Process, Collaboration between OEMs and suppliers for an optimal battery pack design, Home Task - Battery pack design, SORT analysis document.

Topics covered:

Pack Design Steps, Identify Application, Choose cell chemistry, Series –parallel configuration, Choose required BMS, Choose TMS, Choose Pack cabinet and other parts and equipments, Pack Technical Specification.

Battery Pack Cells configuration, Basic calculations that are used in battery design, Case study of different OEM battery, Module BMS connection, Custom Battery Packs - Customization Process, Collaboration between OEMs and suppliers for an optimal battery pack design, Home Task - Battery pack design, SORT analysis document.

Key Learning Outcomes:

Choose the right cell chemistry, form factor (cylindrical, prismatic or blade), and capacity based on the specific application's requirements. Identify and understand the role of components like cell holders, bus bars, insulators, and heat sinks in module construction. Evaluate the design's performance under different operating conditions.11. Battery Pack Assembly Line and Financial Projection

Setting up a battery pack assembly line involves several key stages, from initial cell preparation to final testing and quality control

Topics covered:

KEY MANUFACTURING (PRODUCTION) METRICS, Essential quality metrics, Time Metrics, Assembly Line equipments, Market Trends in Lithium-Ion Battery Industry, Renewable Energy Storage, Electric Vehicles (EVs), Consumer Electronics, Energy Storage Solutions, How Can We Make Lithium-Ion Battery Production Cheaper, Main Revenue Streams, Financial Discloser

Topics covered:

KEY MANUFACTURING (PRODUCTION) METRICS, Essential quality metrics, Time Metrics, Assembly Line equipments, Market Trends in Lithium-Ion Battery Industry, Renewable Energy Storage, Electric Vehicles (EVs), Consumer Electronics, Energy Storage Solutions, How Can We Make Lithium-Ion Battery Production Cheaper, Main Revenue Streams, Financial Discloser

Key Learning Outcomes:

Developing the technical specifications for the assembly line, including equipment selection and factory layout considerations. Estimating project costs, working capital, and calculating the return on investment (ROI) for the assembly line. Creating a comprehensive business plan, including securing funding and managing financial aspects of the venture.12. Charging Infrastructure and Site Assessment

A comprehensive understanding of charging technologies including their components, benefits, and different types of charging modes.

A charging station site assessment class equips participants to perform a comprehensive site suitability analysis,

considering factors like energy infrastructure, grid capacity, land usage, socio-demographics, and traffic patterns to

identify optimal locations for new EV charging stations.

Topics covered:

Introduction to EV Charging technology, Onboard charging and Off-board charging, AC charging vs DC charging, AC charging - Type 1,2,3, DC charging - Chademo, Tesla, CCS, Fast charging, Different types of EV charger connectors, SAE J1773, CHAdeMO standard - DC fast charging, National & International EV Standard Codes

Choosing the location - Public charging stations, Site Selection Considerations, General Site Issues, URDPFI Guidelines, Planning Considerations.

Key learning outcomes include applying site assessment methodologies, understanding relevant regulations, analyzing energy and grid requirements, evaluating different charging technologies.

Topics covered:

Introduction to EV Charging technology, Onboard charging and Off-board charging, AC charging vs DC charging, AC charging - Type 1,2,3, DC charging - Chademo, Tesla, CCS, Fast charging, Different types of EV charger connectors, SAE J1773, CHAdeMO standard - DC fast charging, National & International EV Standard Codes

Choosing the location - Public charging stations, Site Selection Considerations, General Site Issues, URDPFI Guidelines, Planning Considerations.

Key Learning Outcomes:

Acquire knowledge on planning and implementing efficient EV charging systems, considering technological, economic, and regulatory frameworks.Key learning outcomes include applying site assessment methodologies, understanding relevant regulations, analyzing energy and grid requirements, evaluating different charging technologies.

13. Charging Station Design

Understand and size essential electrical components like cables, panels, and transformers for AC and DC charging station.

Topics covered:

Guidelines on Charging Infrastructure, Public Charging Infrastructure (PCI) - Components of charging station, Proposed Tariff for EV Charging, Design Grid charging stations for a parking lot, Single line diagram of charging station.

Topics covered:

Guidelines on Charging Infrastructure, Public Charging Infrastructure (PCI) - Components of charging station, Proposed Tariff for EV Charging, Design Grid charging stations for a parking lot, Single line diagram of charging station.

Key Learning Outcomes:

knowledge of power system components like cables, DC/AC fast-charging capabilities, grid integration, battery technology, relevant electrical standards, and the capacity to perform site-specific load calculations and create single-line diagrams.14. Overall discussion and Business Guide

EV Charging Station and Lithium-ion battery pack business can be profitable with careful planning and execution.

Key aspects include market research, business plan development, securing funding and permits, establishing manufacturing or assembly operations, and implementing robust safety and quality control measures.

Topics covered:

Training Session Review, Project Submission and Examination,

Starting Business: Trade Name Registration, Steps to Starting a Lithium-ion battery Business, Trademark Registration, GST and MSME registrations, Website Development for Business, Business and Branding Strategy, Marketing and Promotion, Website Optimization and Visibility, Product certification, Government Initiatives, Supplier and Agency Networking, Project Proposals and Securing Work, Partnerships OEM and Post-Training Support from Academy of EV Technology.

Topics covered:

Training Session Review, Project Submission and Examination,

Starting Business: Trade Name Registration, Steps to Starting a Lithium-ion battery Business, Trademark Registration, GST and MSME registrations, Website Development for Business, Business and Branding Strategy, Marketing and Promotion, Website Optimization and Visibility, Product certification, Government Initiatives, Supplier and Agency Networking, Project Proposals and Securing Work, Partnerships OEM and Post-Training Support from Academy of EV Technology.

Quick Inquiry Form

Interactive Session

Practical & Doubt Session

E-Library Study Materials

Online Evaluation