Electric Vehicle Course Categories

- Master Degree

- PG Course

- Startups/Business Course

- Job Course

- Research and Development

Masters Degrees (Electric Vehicles)

| Program Title | University | Duration |

|---|---|---|

| Master in Electric Vehicle Engineering | Sweden’s leading university | one-year programme |

| MSc Mobility Engineering | Politecnico | 2 years |

| MSc Automotive Engineering for Electric Vehicles | University of Bedfordshire | 1 yera |

| PG Program in Electric Vehicle Powertrain | Joint program with UPES and Academy of EV Technology | 10 Months |

| Certificate in EV Technology | Joint program with UPES and Academy of EV Technology | 3 Months |

Startups/Business Course

| Program Title | Offered by | Duration |

|---|---|---|

| EV EVSE Business Management Course for Entrepreneurs | Academy of EV Technology | one Month |

| Lithium-ion Battery Pack Assembly Line | Academy of EV Technology | One Month |

| Electric Vehicle Charging Station Design, Installation | Academy of EV Technology | 1 Month |

| Program Title | Offered by | Duration |

|---|---|---|

| PG Program in Electric Vehicle Powertrain | Joint program with UPES and Academy of EV Technology | 10 Months |

| Certificate in EV Technology | Joint program with UPES and Academy of EV Technology | 3 Months |

Certificate course - Fundamental of PHEV & BEV

Hybrid vehicle is that propels itself using both a conventional engine and an electric motor.

Plug-in hybrids have a smaller battery that typically allows an electric range of 20-50 miles, and a gasoline combustion engine that adds another 300 to 500 miles of driving range.

Battery electric vehicles are driven only by their battery and electric motor and typically have ranges of 125-300 miles.

Prior to 2018 the market was split roughly 50/50 between plug-in hybrid and battery electric vehicles. However, in 2018 the market shifted to 66% battery electric vehicle and 34% plug-in hybrids.

Although they have many advantages, the future for PHEVs still looks bleak. some reasons are PHEVs fuel expensive, they are complex to maintain, all-electric vehicles, which have a long range and a high performance.

Buyers are now looking forward to all-electric vehicles and will hit the market. The future of plug-in hybrids will be very competitive. It is expected that the PHEVs will disappear when the public gains awareness of the BEVs.

By 2030, not a single petrol or diesel car should be sold in the country. Piyush Goyal, India's minister for power, coal, and new and renewable energy

According to various sources,The United Kingdom has committed to a plan to ban all sales of gasoline and diesel-engine cars by 2040.

The French government, not to be outdone, says they will match the UK's plan for combustion-engine cars by 2040. Many German cities have already started to ban older, more polluting cars from their roads.

India are planning to remove all diesel-engine cars from their roads by 2030.

Norway plans to make sure all new cars are zero-emissions by 2025.

Hainan,(China) with a population of more than 9 million residents, aims to entirely eliminate ICEs in the province by 2030

Taiwan hoping to stop the sales of all new diesel and gasoline engine motorcycles by 2035 and four-wheeled vehicles by 2040.

EVs drive new skills requirements in the automotive industry

A working knowledge of basic automotive components and general maintenance necessary for vehicle operations will be emphasized. This course also promotes a basic understanding of alternative fuel and HEV vehicle technology. Electrical engineers design, develop, test, and supervise the manufacture of electrical components. They are responsible for designing the electrical circuitry that allows a gas engine to charge the battery and distribute the electricity from the battery to the electric motor. Electrical engineers also might work on the heating and air-conditioning systems, vehicle lighting, and visual displays. Mechanical engineers design, develop, and test the tools, engines, machines, and other mechanical devices in electric vehicles. Electric vehicle systems are more complex than a traditional internal combustion engine, so they require special manufacturing processes. Many of the workers involved in the manufacture of electric vehicles have previously worked in traditional vehicle manufacturing. As the number of plug-in hybrids and battery-electric vehicles on the road increases, there will be a growing need for charging stations to charge them. Many large utilities companies and some large cities are already developing plans to handle growing numbers of electric vehicles.jobs will be created as the electric infrastructure is expanded to support these vehicles. These new jobs will cover a wide variety of occupations.

Solar cars

Think of how wonderful it would be if your car could continue running without you spending one Rupee on fuel. The car which can be driven for 300-400 kms at the top speed of 50 km/ hour, can charged by four solar panels of seven amperes current and 53 volts each.Solar car that can charge itself with integrated solar energy capacity. The German startup, Sono Motors, Sion Solar Car is the first mass-produced electric car.

Do you want to build a solar-powered car? If so, this is the project for you! This training give you fundamental concept, how can you convert fuel powered car to solar powered electric vehicle and enjoy energy independent trip every day any where. After gaining this fundamental, you can join at AEVT upcoming special course to do energy independent rectrofitment, fuel car to Solar Car, Electric Car to Solar Car.

No experience needed. If you want, you can even compete the Solar technology training from Institute of Solar Trchnology

Business Model Innovation

You want to drive innovation more effectively in your organization, for your business models, learn from successful innovators. Our national International guest lecturer equips you with skills to think more creatively and apply your ideas more effectively.You will also learn concrete techniques to help you nurture a culture of innovation within a team or organization, by maximizing the talent and creativity of those around you.

Must Read more from "WHY AEVT" above section.

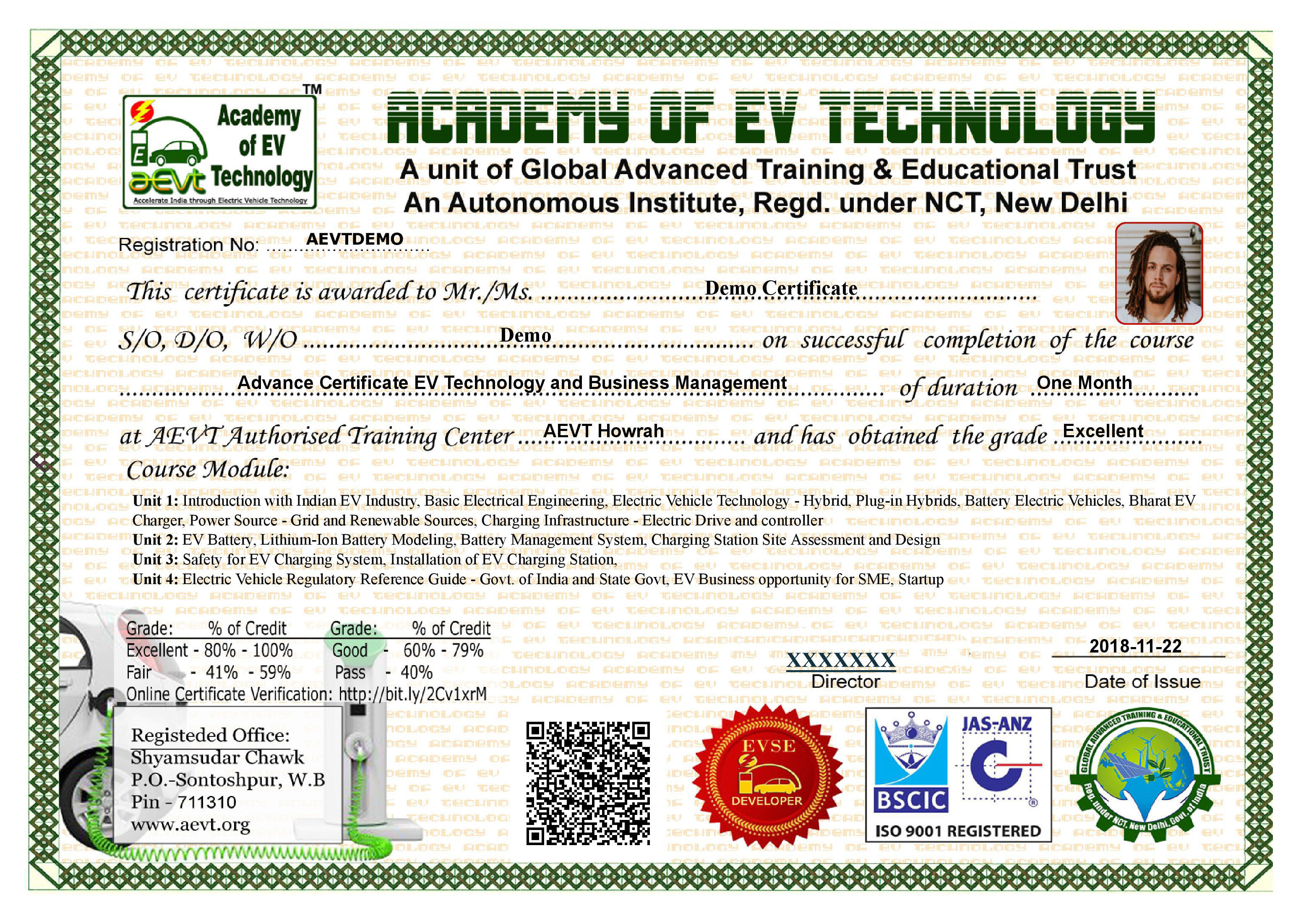

Certificate will be Awarded by

Academy of EV Technology, A Unit of Global Advanced Training & Educational Trust, Regd. under NCT New Delhi, Govt. of India

Eligibility

- Automobile engineer, Entrepreneurs

- Graduation in any stream

- Minimum age 18 years, No Upper Age bar for Entrepreneurs

Medium:

English & Local Language

(Book & Online Examination in English)

Training Methodology:

The course will be delivered in class room board work, lecture using PowerPoint, sharing of case examples, design exercises.

Training Materials:

- FREE printed book as per Syllabus developed by National and International EV Technology Trainer & Expert

- EVSE, sample financial models etc.

- Training & Learning Materials: Wall Chart, Equipment, Measuring Meters, accessories and tools for practical & demonstration only

We believe in "Learn-through-Practical"

- 1. AEVT follows 70% practical and 30% theory

- 2. Developing practical knowledge and skill on Motor, Controller, Battery Pack Design, BMS, Charger equipments and Charging Station

- 3. Discussion on Industrial scenario and business opportunities

- 4. Unit wise practical Activities

Course Syllabus:

| Unit | Code | Paper Detail |

|---|

Next Batch Admission Going-on: Limited Seats! Contact with Admission Depertment

Course Fee for 72 hours (within one month) Entrepreneurship Training - Advance Certificate EV Technology & Business Management

Course Fee for Indian Students

| # | Fees detail | Amount |

|---|---|---|

| 1 | Registration Fee | Rs.3000 |

| 2 | Training Fee | Rs. |

| 3 | E-Libery Fee | Rs. 00.00 |

| 4 | Study Material Fee | Rs. 00.00 |

| 5 | Exam Fee | Rs. 00.00 |

GST @18% Extra |

Course Fee for International Students

| # | Fees detail | Amount |

|---|---|---|

| 1 | Registration Fee | $ 42 |

| 2 | Training Fee | $99 |

| 3 | E-Libery Fee | $ 00.00 |

| 4 | Study Material Fee | $ 00.00 |

| 5 | Exam Fee | $ 00.00 |

GST @18% Extra |

Become an EV Expert with Verified Skill Certification

1. An Autonomous Institute registered under NCT, Govt. of India under Indian Trust Act.

2. Registered Under NGO-DARPAN, NITI Aayog Govt. of India

3. ISO 9001:2015 registered Educational Trust

4. Registered under 80G and 12A and CSR Act, Govt. of India

5. Practical and Research Lab at GATE Trust Howrah, West Bengal

6. GATE Research - Research unit of Global Advanced Training and Educational Trust. You can Write & Publish a Review/Research paper,

Quick Inquiry Form

Interactive Session

Practical & Doubt Session

E-Library Study Materials

Online Evaluation