Electric Vehicle Course Categories

- Master Degree

- PG Course

- Startups/Business Course

- Job Course

- Research and Development

Masters Degrees (Electric Vehicles)

| Program Title | University | Duration |

|---|---|---|

| Master in Electric Vehicle Engineering | Sweden’s leading university | one-year programme |

| MSc Mobility Engineering | Politecnico | 2 years |

| MSc Automotive Engineering for Electric Vehicles | University of Bedfordshire | 1 yera |

| PG Program in Electric Vehicle Powertrain | Joint program with UPES and Academy of EV Technology | 10 Months |

| Certificate in EV Technology | Joint program with UPES and Academy of EV Technology | 3 Months |

Startups/Business Course

| Program Title | Offered by | Duration |

|---|---|---|

| EV EVSE Business Management Course for Entrepreneurs | Academy of EV Technology | one Month |

| Lithium-ion Battery Pack Assembly Line | Academy of EV Technology | One Month |

| Electric Vehicle Charging Station Design, Installation | Academy of EV Technology | 1 Month |

| Program Title | Offered by | Duration |

|---|---|---|

| PG Program in Electric Vehicle Powertrain | Joint program with UPES and Academy of EV Technology | 10 Months |

| Certificate in EV Technology | Joint program with UPES and Academy of EV Technology | 3 Months |

Market Research Reports & Industry Analysis

LITHIUM-ION CELL MANUFACTURING: Detailed Techno-Economic Feasibility Report

Lithium Ion Battery Market Overview:

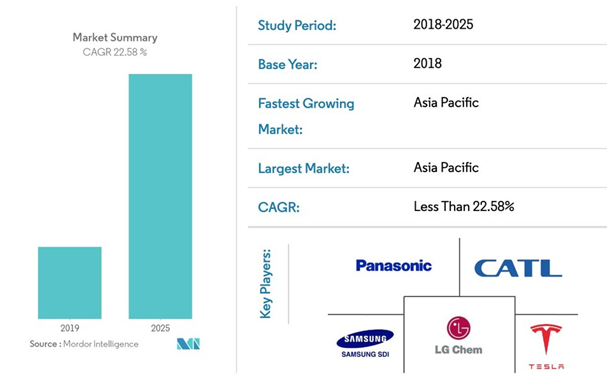

Global lithium ion battery market was valued at $30,186.8 million in 2017, and is projected to reach $100,433.7 million by 2025, growing at a CAGR of 17.1% from 2018 to 2025. Asia-Pacific region is expected to occupy the largest share of the global lithium ion battery market in 2018.

The market for lithium-ion battery is expected to register a CAGR of 22.58%, during the forecast period (2020-2025). Major factors driving the market studied are the emergence of new and exciting markets, via electric vehicle and energy storage systems (ESS), for both commercial and residential applications, declining lithium-ion battery prices, and the increasing sale of consumer electronics. However, the increasing demand-supply mismatch of raw materials is likely to hinder the growth of the market studied.

The Government of India (GoI) recently announced plans for transition to all electric transportation by 2030. GoI also introduced the Faster Adoption and Manufacturing of Hybrid and Electric Vehicles (FAME) policy in 2015, to increase the adoption of Electric Vehicles (EVs) on the road. Considering that the battery and related components account for about 40-50% of the EV cost, the overall manufacturing plant of 50 GWh capacity has been considered.

The Indian electric vehicle (EV) market will continue to be largely driven by the two-wheeler and three-wheeler segment, experts opined at the ETAuto Virtual Roundtable on ‘Post Covid-19: Future of Electric Vehicles Global and India’.

According to them the EV market will recover swiftly from Covid-19 setback when compared to their ICE counterparts and their outlook remains strong in the medium term.

By 2025, 30-35 percent of sales are expected to be electric which includes mild hybrid, full hybrids, plug-in, and battery. In terms of battery electric vehicles, about 10-12 percent of global sales will be fully electric.

For companies, entrepreneurs and businesses keen on setting up Li-ion Battery Packs assembling unit, this is best time. This market survey techno-commercial report will help you very much.

Table of Contents

1. Terms used in the project report

2. Globally current application of lithium-ion battery storage

3. OEMs Battery pack manufacturing strategy

4. Lithium-ion Battery Manufacturers in India

5. Introduction with Lithium-ion and EV

6. Introduction with Battery Pack

7. Lithium-ion chemistry

8. Li-ion cell to battery-pack value chain

9. Design Considerations

10. LITHIUM ION BATTERY TYPES

11. Plant Layout

12. PLANT LOCATION FACTORS

13. Environment: Applicable Regulatory Framework and Environmental Impact of Project

14. License, certificate and Approval

15. Project Technical Concept

16. Assembling process of lithium ion battery

17. Li ion battery assembly Line

18. Production line layout

19. Battery Cost Effect

20. Effects of Cell Chemistry on Battery Cost

21. Type of production unit

22. MACHINERY AND EQUIPMENTS

23. Machinery and equipments suppliers

24. Packaging Material Solutions for Battery Manufacturing

25. Transportation of Battery pack

26. Battery Waste Management

27. Slandered Code

28. Test Certification

29. Battery Pack Manufacturing Investment Costs

30. Plant Economics

31. Fixed Capital, Working Capital, Capital Investment

32. Cost of production/annum

33. Turn Over/Annum

34. Risks & Mitigation

35. Human Resources

36. Business guide line

37. Address of financial institutions

38. Address of relevant government offices

EVOLT is consulting, research and academic institute specialized in the electric vehicles. We continuously work to establish mutually beneficial relationships with customers, dealers, sales partners and the public administration.

EVOLT collaborates actively with authorities and decision makers globally to secure that relevant research platforms and environments are available where cross-disciplinary research collaborations can take place in areas of common interest.

EVOLT Research Paper:-

Objective of Techno-Economic Feasibility Studies/ Detailed Project Reports is to determine the technical feasibility and financial viability of the project, assess the risks associated with the project and enumerate imminent actions that are required to be taken. It helps a client get a detailed evaluation of a project.

Methodology:

- Broad methodology of execution involves:

- Data collection

- Data analysis

- Report and Project formulation

Benefits:

It helps a client make an investment decision based on:

- Technical feasibility of the project

- Financial viability of the project

- The risks associated with the project

- Actions required for risk mitigation

EVSE Infrastructure Consulting

EVOLT provides nationwide safe, reliable and robust EVSE solutions. Our experienced consultants can help you plan your EV charger selection as per Govt. of India policy and installation from start to finish - from site verification and feasibility through permitting and approvals and software app selection, and all necessary steps, including the commissioning of the final installation.

Download PDF

Project Report, Techno-Economic Feasibility Report Price: Rs. 40000 Rs. 30000 + 18% GST

DOWNLOAD SAMPLE PROJECT REPORT

More Related Project

Interactive Session

Practical & Doubt Session

E-Library Study Materials

Online Evaluation