EV Battery Thermal Management System

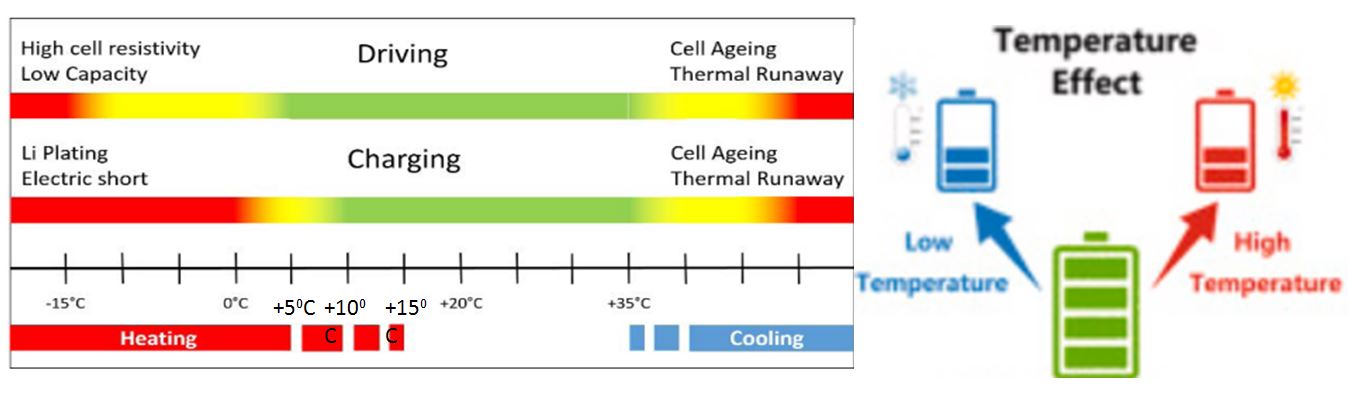

EV Battery Thermal Management System to

- Cooling

- Heating

Life cycle or calander life of cells

Non-Uniform Aging

Thermal Ranaway

Safety

So, we need to cool battery by active cooling or passive cooling system

Before calculate amount of heat can generate in a battery pack, we need to clear from where heat generate? Heat can generate in the cell, in busbar, BMS, Mosfet, Shunt by IxIxR . So, if we can measure accurately or calculate accurately, we can design at temperatuure range it can work.

EV Battery pack assembly line course Topic are not limited to the items below, more related to battery Thermal Management mechanism :

- Air cooling system

- Liquid cooling system

- Refrigent cooling system

- Phase change materials cooling

Battery Expert at

Academy of EV Technology (AEVT) and Energy Materials Research Centre (EMRC)

M.Sc Physics, Future Energy Storage researcher

M: 918479838828

Interactive Session

Practical & Doubt Session

E-Library Study Materials

Online Evaluation