Find EV EVSE course

Lithium-ion battery market at your city

Opportunities for the lithium-ion battery business in and around Asansol include electric vehicle (EV) battery solutions, renewable energy storage systems, and battery servicing and recycling, driven by rising demand for EVs and sustainable energy.

As the demand for EVs in India rises, there is a growing market for selling EV batteries and setting up charging infrastructure. You can provide repair, maintenance, and recharge services for EV batteries, a growing need as more EVs are deployed.

The best online electric vehicle (EV) course provide "Academy of EV Technology (AEVT)" for working professionals include the Certificate Programme on eMobility. For business owners, the best electric vehicle (EV) online courses are those focused on business management and practical skills for the EV market, such as the AEVT "EV Technology and Business Management" or "Lithium-ion Battery Assembly Line for battery production" that provide a solid foundation in EV technology, business, and management.

For a battery company, EV dealers, sellers the best online courses focus on advanced battery technology, such as the "Lithium-ion Battery Assembly Line for battery production" which covers electrochemical cells, battery materials, and industrial applications, or courses on Battery Management Systems (BMS) offered by "Academy of EV Technology (AEVT)".

Solar Energy and Lithium Batteries Courses

Solar Energy and Lithium Batteries Courses at Institute of Solar Technology (https://istindia.org ) and Academy of EV Technology (https://aevt.org ) cover practical assembly, business management, and system design, with options for online and offline learning, and cover topics from basic cell selection to complex pack assembly and ROI calculation.Institute of Solar Technology (https://istindia.org ) and Academy of EV Technology (https://aevt.org ) offer specialized courses for both technicians and entrepreneurs interested in the growing solar and battery industry.

Ev Charging Station Course

Business/Entrepreneurial Courses:Guide individuals on how to start and manage an EV charging station business, covering market trends, business opportunities, and necessary infrastructure.

Ev Charging Station Course

Advance Courses Available

Solar Application Li-ion Battery Manufacturing Course , Focuses on the practical setup of battery assembly lines, covering cell selection, testing, module assembly, and business planning such as costing and investment.PV Technology and Business Management (Online), Targets individuals interested in starting businesses in the solar sector, covering technical aspects and business management.

Solar Project Design Master Course (Online), Aimed at engineers, focusing on designing solar projects.

Li-ion Battery Pack Assembly (Online), Provides detailed instructions on how to assemble lithium-ion battery packs.

Enhance knowledge on EV & EVSE, Lithium battery through engaging in thoughtful discussions, or participating in online session, actively seeking knowledge challenges your thinking, expands your horizons, and enhances your analytical and critical thinking skills.

This is an advance program in Knowledge Enhancement and Learning Development that redefines your approach to your profession and expands your creative vision. It focuses on training your mind to increase its capacity for strategic thinking, innovative exploration, and knowledge advancement.

Future Trends in Lithium Battery Technology

Recent Advancements in Lithium Battery Technology

1. Enhancements in Energy Density and PerformanceReplacing traditional graphite anodes with silicon anodes could further boost energy density by 20-40%, potentially reaching 400 Wh/kg.

2. Advances in Safety Features and Thermal Stability, such as advanced electrolyte formulations and improved separator materials, further enhance thermal stability. These innovations ensure that lithium-ion batteries can operate safely under extreme conditions, making them suitable for demanding environments like industrial automation and electric vehicles.

3. Faster Charging and Extended Lifespan, focuses on achieving a lifespan of 1000 cycles over 15 years through improved electrolyte transport and thermal management.

4. Smart Battery Management Systems and AI Integration, smart BMS can help you achieve sustainable energy storage with maximizing operational efficiency

EV 2 wheeler Battery Replacement Cost - Rs 15000 to Rs 30000

Lithium IonBattery for Electric Two Wheelers 48V 29 AH48volt 32AH Smart Mobile BMS Electric Scooter Bike Lithium Battery Pack

60volt 32AH Electric Scooter with Lithium Battery Pack

48V 26AH 85KM+ Mileage Lithium Ion Battery For Electric Scooter, Bike

EV 3 wheeler Battery Replacement Cost Rs 40000 to Rs 90000

60.8V 100Ah LFP Battery for High-Range 3-Wheeler EVElectric Rickshaw Lithium Prismatic Battery Pack

48v/45ah Lithium-ion Battery Nmc

Electric Car Battery Replacement Cost

Small (up to 30 kWh) ₹4,50,000 – ₹6,00,000Moderate (30-60 kWh) ₹6,00,000 – ₹9,00,000

Large (Above 60 kWh) ₹9,00,000 – ₹12,00,000

According to market research, battery prices are predicted to fall to ₹8,000 per kWh of storage capacity.

Lithium-ion Battery pack assembly

Techno Commercial knowledge to setup Lithium-ion battery assembly line for solar application, energy storage and EV 2W, 3W etc.

Practical skills - cell sellection, cell IR testing, cell balancing, charge discharge testing, module & pack assembling, enclosure selection, all machinery selection, assembly line planning and layout drawing, costing of assembly line, working capital, investment, ROI, business projection making, different product design.

Course Outcome:

Get the knowledge of Lithium-ion cell parameters, Cell Chemistry, Cell Architecture, Thermal Management, BMS and battery pack assembly technical and commercial detail before setup assembly line.

Today's Offer: FLAT 15% discount for online session

MINISTRY OF ROAD TRANSPORT AND HIGHWAYS

NOTIFICATION

New Delhi, the 11th November, 2025

All E-rickshaw or E-cart manufactured on or after the 1st day of April, 2027 shall be fitted with lithium-ion battery packs and the performance requirements of the same shall be as per AIS-156 (Part 1) and (Part 2), as amended from time to time.”.

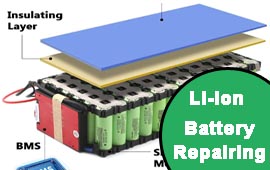

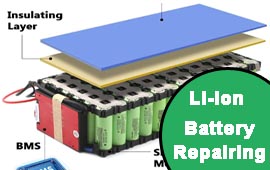

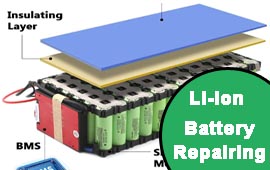

EV Lithium-ion Battery Repair and Maintenance

Course Overview:

Electric cars are becoming increasingly popular, and with that comes the need for high-quality battery repair centers. By repairing batteries, they are able to extend the lifespan of batteries considerably.The average electric vehicle lithium-ion battery can retain up to 70% of its charging capacity after being removed. The business proposition for second-life batteries is therefore intuitive The second life market looks set to boom in the coming years as EV uptake grows.

Course Outcome:

Get the knowledge of Lithium-ion cell parameters, Cell Chemistry, Cell Architecture, Thermal Management, BMS and battery pack technical and commercial detail before start Repair shop.Today's Offer: FLAT 15% discount for online class

Lithium-ion battery sector

The market for battery swapping services in India is bifurcated at present, with different players incorporating diverse battery types for various kinds of vehicles. Locating suitable charging infrastructure and connections may be challenging in the aftermath of the stated measure. As a result of the utilisation of sub-standard batteries, there have also been occurrences of fires at battery-switching facilities.

In 'white gold' rush, India kick-starts talks with lithium-rich nations

Jammu and Kashmir's reserve might be present with a large amount of lithium, but the current amount is insufficient to match with the world's top reserves of Lithium. For India to become self-reliant in the field of solar energy storage and EV manufacturing without being dependent on China for EV battery supplies, it is important to own more such Lithium reserves and enhance its presence in overseas lithium mines. Solar lighting system operates on electricity from batteries, charged through the use of solar photovoltaic panels. It is composed of a battery, solar panel, LED lamp, and charge controller. The stored energy is collected in a rechargeable Lithium-ion battery used later to produce lighting at night. The rapid infrastructure development in all sectors of India is pushing local solar light manufacturers to compete and deliver innovative solar lighting products at low prices to increase their presence in the market.

Lithium-ion Battery pack assembly

Techno Commercial knowledge to setup Lithium-ion battery assembly line for solar application, energy storage and EV 2W, 3W etc.

Practical skills - cell sellection, cell IR testing, cell balancing, charge discharge testing, module & pack assembling, enclosure selection, all machinery selection, assembly line planning and layout drawing, costing of assembly line, working capital, investment, ROI, business projection making, different product design.

Course Outcome:

Get the knowledge of Lithium-ion cell parameters, Cell Chemistry, Cell Architecture, Thermal Management, BMS and battery pack assembly technical and commercial detail before setup assembly line.

Today's Offer: FLAT 15% discount for online session

MINISTRY OF ROAD TRANSPORT AND HIGHWAYS

NOTIFICATION

New Delhi, the 11th November, 2025

All E-rickshaw or E-cart manufactured on or after the 1st day of April, 2027 shall be fitted with lithium-ion battery packs and the performance requirements of the same shall be as per AIS-156 (Part 1) and (Part 2), as amended from time to time.”.

EV Lithium-ion Battery Repair and Maintenance

Course Overview:

Electric cars are becoming increasingly popular, and with that comes the need for high-quality battery repair centers. By repairing batteries, they are able to extend the lifespan of batteries considerably.The average electric vehicle lithium-ion battery can retain up to 70% of its charging capacity after being removed. The business proposition for second-life batteries is therefore intuitive The second life market looks set to boom in the coming years as EV uptake grows.

Course Outcome:

Get the knowledge of Lithium-ion cell parameters, Cell Chemistry, Cell Architecture, Thermal Management, BMS and battery pack technical and commercial detail before start Repair shop.Today's Offer: FLAT 15% discount for online class

Online courses for working professionals

The major guidelines proposed by this department - The minimum requirement for installation of a public charging station must include exclusive transformer, 33/11 kV lines, proper civil works, and appropriate liquid cooled cables. Moreover, the public charging stations must be tested by respective authorities before operation.

The availability of suitable charging sites is great concerned. The estimate of EV supply hardware essential at assorted kinds of areas is proposed dependent on a charging technique. Both convenience and physical concerns should be considered for effective charging stations.

Keeping the above mentioned opportunities in the EV market, AEVT has designed Entrepreneurship Development Programme on Electric Vehicle Charging Station so as to provide overview of the EV ecosystem and the systematic approach on planning, and execution of EV charging infrastructure.

Solar Power EV Charging Station

Solar Power Electric Vehicle Charging Station

Course Overview:

Solar charging stations for electric vehicles have emerged as one of the best ways to reduce India’s dependence on fossil fuels. Nearly everyone who owns an Electric vehicle will install a solar charging station in their home. Solar-powered EV charging stations are the solution to bring that percentage down to zero.Course Outcome:

Solar Power EV Charging Station (Design and Development) Program is a master program that takes an Engineer, designe engineer, installer from site assessment, all the way through power-up and pinpointing. Installers who take this knowledge will have all the information needed to efficiently and accurately assess, design and install charging stations.Today's Offer: FLAT 15% discount for online Session

In 'white gold' rush, India kick-starts talks with lithium-rich nations

Jammu and Kashmir's reserve might be present with a large amount of lithium, but the current amount is insufficient to match with the world's top reserves of Lithium. For India to become self-reliant in the field of solar energy storage and EV manufacturing without being dependent on China for EV battery supplies, it is important to own more such Lithium reserves and enhance its presence in overseas lithium mines. Solar lighting system operates on electricity from batteries, charged through the use of solar photovoltaic panels. It is composed of a battery, solar panel, LED lamp, and charge controller. The stored energy is collected in a rechargeable Lithium-ion battery used later to produce lighting at night. The rapid infrastructure development in all sectors of India is pushing local solar light manufacturers to compete and deliver innovative solar lighting products at low prices to increase their presence in the market.

Lithium-ion Battery pack assembly

Techno Commercial knowledge to setup Lithium-ion battery assembly line for solar application, energy storage and EV 2W, 3W etc.

Practical skills - cell sellection, cell IR testing, cell balancing, charge discharge testing, module & pack assembling, enclosure selection, all machinery selection, assembly line planning and layout drawing, costing of assembly line, working capital, investment, ROI, business projection making, different product design.

Course Outcome:

Get the knowledge of Lithium-ion cell parameters, Cell Chemistry, Cell Architecture, Thermal Management, BMS and battery pack assembly technical and commercial detail before setup assembly line.

Today's Offer: FLAT 15% discount for online session

MINISTRY OF ROAD TRANSPORT AND HIGHWAYS

NOTIFICATION

New Delhi, the 11th November, 2025

All E-rickshaw or E-cart manufactured on or after the 1st day of April, 2027 shall be fitted with lithium-ion battery packs and the performance requirements of the same shall be as per AIS-156 (Part 1) and (Part 2), as amended from time to time.”.

EV Lithium-ion Battery Repair and Maintenance

Course Overview:

Electric cars are becoming increasingly popular, and with that comes the need for high-quality battery repair centers. By repairing batteries, they are able to extend the lifespan of batteries considerably.The average electric vehicle lithium-ion battery can retain up to 70% of its charging capacity after being removed. The business proposition for second-life batteries is therefore intuitive The second life market looks set to boom in the coming years as EV uptake grows.

Course Outcome:

Get the knowledge of Lithium-ion cell parameters, Cell Chemistry, Cell Architecture, Thermal Management, BMS and battery pack technical and commercial detail before start Repair shop.Today's Offer: FLAT 15% discount for online class

Quick Inquiry Form

Class Time / Slot

Online class Available slot for working professionals

Available slot: December month

| Slot | IST Time | Status |

| 1 | 7:30 AM - 9:00 AM 4th Batch (Last Batch) | |

| 2 | 10:30 AM - 12:00 Noon | |

| 3 | 3:00PM - 4:30PM 3rd Batch | |

| 4 | 8:00 PM - 9:30PM 1st & 2nd Batch |

Next batch Class will start from January - 2026

| Slot | IST Time | Status |

| 1 | 7:30 AM - 9:00 AM | |

| 2 | 10:30 AM - 12:00 Noon | |

| 3 | 3:00PM - 4:30PM | |

| 4 | 8:00 PM - 9:30PM |

| Slot | IST | WAT | SAST | EAT | KST |

| 1 | 7:30 AM | 3 AM | 4 AM | 5 AM | 10 AM |

| 2 | 10:30 AM | 6 AM | 7 AM | 8 AM | 1 PM |

| 3 | 3 PM | 10:30 AM | 11:30 AM | 12:30 PM | 5:30 PM |

| 4 | 8 PM | 3:30 PM | 4:30 PM | 5:30 PM | 10:30 PM |

4 Slot 4 batch each slot

Admission Going on for

EV Technology and Business Management - Techno Commercial Training (online)

Today's 15% Discount From:

January - 2026

Course Duration: 2 + 1 Months

EV Battery Pack Assembly Line Training (online)

Today's 15% Discount From:

January - 2026

Course Duration: 2 + 1 Months

Solar Power EV Charging Station (online)

Today's 15% Discount From:

January - 2026

Course Duration: 2 + 1 Months

Visit our Google Map

View all Job