Find EV EVSE course

Lithium-ion battery market at your city

Business opportunities for lithium-ion batteries in Howrah include battery pack assembly for electric vehicles (EVs), energy storage systems (ESS) for renewable energy, and lithium battery wholesaling and distribution to supply growing demand from various sectors. Become a wholesaler to supply batteries to local businesses and individuals for residential, commercial, and EV-related needs.

Enhance knowledge on EV & EVSE, Lithium battery through engaging in thoughtful discussions, or participating in online session, actively seeking knowledge challenges your thinking, expands your horizons, and enhances your analytical and critical thinking skills.

This is an advance program in Knowledge Enhancement and Learning Development that redefines your approach to your profession and expands your creative vision. It focuses on training your mind to increase its capacity for strategic thinking, innovative exploration, and knowledge advancement.

Future Trends in Lithium Battery Technology

Recent Advancements in Lithium Battery Technology

1. Enhancements in Energy Density and PerformanceReplacing traditional graphite anodes with silicon anodes could further boost energy density by 20-40%, potentially reaching 400 Wh/kg.

2. Advances in Safety Features and Thermal Stability, such as advanced electrolyte formulations and improved separator materials, further enhance thermal stability. These innovations ensure that lithium-ion batteries can operate safely under extreme conditions, making them suitable for demanding environments like industrial automation and electric vehicles.

3. Faster Charging and Extended Lifespan, focuses on achieving a lifespan of 1000 cycles over 15 years through improved electrolyte transport and thermal management.

4. Smart Battery Management Systems and AI Integration, smart BMS can help you achieve sustainable energy storage with maximizing operational efficiency

EV 2 wheeler Battery Replacement Cost - Rs 15000 to Rs 30000

Lithium IonBattery for Electric Two Wheelers 48V 29 AH48volt 32AH Smart Mobile BMS Electric Scooter Bike Lithium Battery Pack

60volt 32AH Electric Scooter with Lithium Battery Pack

48V 26AH 85KM+ Mileage Lithium Ion Battery For Electric Scooter, Bike

EV 3 wheeler Battery Replacement Cost Rs 40000 to Rs 90000

60.8V 100Ah LFP Battery for High-Range 3-Wheeler EVElectric Rickshaw Lithium Prismatic Battery Pack

48v/45ah Lithium-ion Battery Nmc

Electric Car Battery Replacement Cost

Small (up to 30 kWh) ₹4,50,000 – ₹6,00,000Moderate (30-60 kWh) ₹6,00,000 – ₹9,00,000

Large (Above 60 kWh) ₹9,00,000 – ₹12,00,000

According to market research, battery prices are predicted to fall to ₹8,000 per kWh of storage capacity.

Lithium-ion Battery pack assembly

Techno Commercial knowledge to setup Lithium-ion battery assembly line for solar application, energy storage and EV 2W, 3W etc.

Practical skills - cell sellection, cell IR testing, cell balancing, charge discharge testing, module & pack assembling, enclosure selection, all machinery selection, assembly line planning and layout drawing, costing of assembly line, working capital, investment, ROI, business projection making, different product design.

Course Outcome:

Get the knowledge of Lithium-ion cell parameters, Cell Chemistry, Cell Architecture, Thermal Management, BMS and battery pack assembly technical and commercial detail before setup assembly line.

Today's Offer: FLAT 20% discount for online session

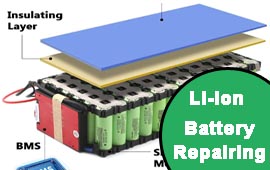

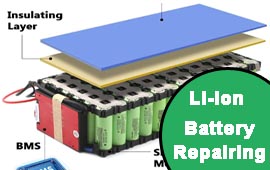

EV Lithium-ion Battery Repair and Maintenance

Course Overview:

Electric cars are becoming increasingly popular, and with that comes the need for high-quality battery repair centers. By repairing batteries, they are able to extend the lifespan of batteries considerably.The average electric vehicle lithium-ion battery can retain up to 70% of its charging capacity after being removed. The business proposition for second-life batteries is therefore intuitive The second life market looks set to boom in the coming years as EV uptake grows.

Course Outcome:

Get the knowledge of Lithium-ion cell parameters, Cell Chemistry, Cell Architecture, Thermal Management, BMS and battery pack technical and commercial detail before start Repair shop.Today's Offer: FLAT 20% discount for online class

Lithium-ion battery sector

The market for battery swapping services in India is bifurcated at present, with different players incorporating diverse battery types for various kinds of vehicles. Locating suitable charging infrastructure and connections may be challenging in the aftermath of the stated measure. As a result of the utilisation of sub-standard batteries, there have also been occurrences of fires at battery-switching facilities.

In 'white gold' rush, India kick-starts talks with lithium-rich nations

Jammu and Kashmir's reserve might be present with a large amount of lithium, but the current amount is insufficient to match with the world's top reserves of Lithium. For India to become self-reliant in the field of solar energy storage and EV manufacturing without being dependent on China for EV battery supplies, it is important to own more such Lithium reserves and enhance its presence in overseas lithium mines. Solar lighting system operates on electricity from batteries, charged through the use of solar photovoltaic panels. It is composed of a battery, solar panel, LED lamp, and charge controller. The stored energy is collected in a rechargeable Lithium-ion battery used later to produce lighting at night. The rapid infrastructure development in all sectors of India is pushing local solar light manufacturers to compete and deliver innovative solar lighting products at low prices to increase their presence in the market.

Lithium-ion Battery pack assembly

Techno Commercial knowledge to setup Lithium-ion battery assembly line for solar application, energy storage and EV 2W, 3W etc.

Practical skills - cell sellection, cell IR testing, cell balancing, charge discharge testing, module & pack assembling, enclosure selection, all machinery selection, assembly line planning and layout drawing, costing of assembly line, working capital, investment, ROI, business projection making, different product design.

Course Outcome:

Get the knowledge of Lithium-ion cell parameters, Cell Chemistry, Cell Architecture, Thermal Management, BMS and battery pack assembly technical and commercial detail before setup assembly line.

Today's Offer: FLAT 20% discount for online session

EV Lithium-ion Battery Repair and Maintenance

Course Overview:

Electric cars are becoming increasingly popular, and with that comes the need for high-quality battery repair centers. By repairing batteries, they are able to extend the lifespan of batteries considerably.The average electric vehicle lithium-ion battery can retain up to 70% of its charging capacity after being removed. The business proposition for second-life batteries is therefore intuitive The second life market looks set to boom in the coming years as EV uptake grows.

Course Outcome:

Get the knowledge of Lithium-ion cell parameters, Cell Chemistry, Cell Architecture, Thermal Management, BMS and battery pack technical and commercial detail before start Repair shop.Today's Offer: FLAT 20% discount for online class

Start Lithium Ion Battery Pack Manufacturing Business

Drone batteries specially optimized for fast charging or delivering particularly high power loads.

Local Lithium-ion battery production is expected to lower the cost of electric vehicles soon.

Continuous developments in lithium battery technology, however, are making agricultural electrification much more attainable.

Agricultural machinery and equipment manufacturers have already begun seizing these opportunities for small- to medium-sized equipment, and this usage will only expand in the coming years.

This means entrepreneurs have great potential to start their lithium-ion battery businesses. The whole process may seem simple, but knowledge and skill required,

like

1. be sure you understand how batteries are made

2. selected which market segment best to enter

3. licenses, permissions, or approvals required for operating a battery factory and many more …

Through all of the potential knowledge and skills, you can be better prepared for whatever comes your way.

Transition to green energy & net zero future is dependent on the availability of key elements such as Cobalt, Lithium, Nickel, Manganese and Graphite, Not just India but the world is deficient looking to the looming demand in near future. sustainable Li-Ion battery recycling is the missing link in the battery supply chain.

Know the eco-friendly recycling competence and know-how that can provide a substantial quantity of these metals to Indian industry as well as internationally for manufacturing of Lithium-Ion Battery.

Government's Strategic Move to Enhance Bharat's Battery Energy Storage

In a significant development aimed at bolstering India's renewable energy sector, the Union

Cabinet has given its nod to a ₹3,760 crore Viability Gap Funding (VGF) initiative dedicated to

battery energy storage systems (BESS). The move holds tremendous promise for the renewable

energy industry, as it seeks to address the intermittent power generation issues associated with

green energy sources.

India is planning to invite bids for an 80 billion rupees ($960 million) incentive program for production of electric vehicle batteries, according to people familiar with the matter.

The demand for batteries is expected to rise to 260 gigawatt hour by 2030, catering to a growing market of electric vehicles, grid-scale energy storage and consumer electronics, according to a report published by research center RMI India and the government’s think tank Niti Aayog.

India's Parliament passed a law allowing the government to auction and mine its newly-discovered reserves of lithium, among other minerals, increasing the mining of the critical raw material for electric vehicle batteries.

Battery Business in India

Before starting a battery business in India, it is important to do market research and learn about the technology and your competitors. What your customers are looking for, whether or not the product is in demand, and if your company has the means of producing or distributing in in large volumes - these are all important points to be considered. Required heavy-duty lithium-ion batteries for the construction, agricultural & mining industries.

lithium battery pack solutions for medical applications

Designing and manufacturing lithium battery pack solutions for medical applications, identify the appropriate lithium chemistry, combined with a properly designed Smart Battery Management System (BMS) that meets the specific needs of medical devices. Many medical device developers now work with Lithium Power, as their professional medical lithium battery maker rather than trying to develop their own battery solution in-house. Working on the technical challenges of integrating the battery power in the way that best promotes performance and safety.

Quick Inquiry Form

Class Time / Slot

Online class Available slot for working professionals

Next batch Class will start from December - 2025

| Slot | IST Time | Status |

| 1 | 7:30 AM - 9:00 AM 4th Batch (Last Batch) | |

| 2 | 10:30 AM - 12:00 Noon | |

| 3 | 3:00PM - 4:30PM 3rd Batch | |

| 4 | 8:00 PM - 9:30PM 1st & 2nd Batch |

| Slot | IST | WAT | SAST | EAT | KST |

| 1 | 7:30 AM | 3 AM | 4 AM | 5 AM | 10 AM |

| 2 | 10:30 AM | 6 AM | 7 AM | 8 AM | 1 PM |

| 3 | 3 PM | 10:30 AM | 11:30 AM | 12:30 PM | 5:30 PM |

| 4 | 8 PM | 3:30 PM | 4:30 PM | 5:30 PM | 10:30 PM |

4 Slot 4 batch each slot

Admission Going on for

EV Technology and Business Management - Techno Commercial Training (online)

Today's 20% Discount From:

December - 2025

Course Duration: 2 + 1 Months

EV Battery Pack Assembly Line Training (online)

Today's 20% Discount From:

December - 2025

Course Duration: 2 + 1 Months

Solar Power EV Charging Station (online)

Today's 20% Discount From:

December - 2025

Course Duration: 2 + 1 Months

Visit our Google Map

View all Job